This procedure will define the parts and procedures necessary to drive the spindle of a Hardinge HSL model Speed Lathe with an AC Induction motor controlled by an AC Variable Frequency Inverter. This procedure replaces the Hardinge Vee Pulleys with the Goodyear Eagle PD Synchronous belt and sprocket system.

The kit should include:

- 1 ea. Motor Mount

- 1 ea. 2HP AC Motor

- 1 ea. Goodyear Y-38S-SH Sprocket

- 1 ea. Bushing for the Sprocket

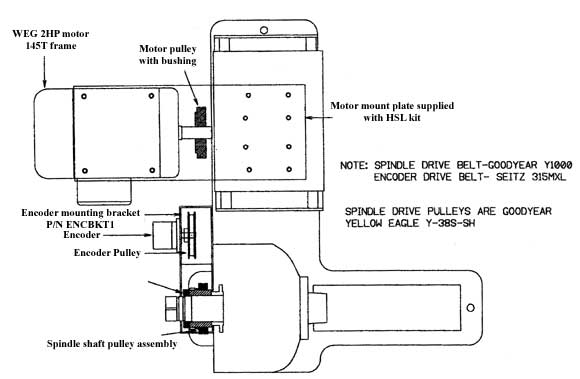

- 1 ea Encoder Mounting Bracket,P/N ENCBKT1

- 1 ea. Spindle Encoder with mounting screws and backplate

- 1 ea. Encoder Pulley

- 1 ea. Spindle Shaft Pulley Assembly

- 1 ea. 1/8 Key Stock, 1.625 long

- 1 ea. Spindle Drive Belt P/N GOODYEAR Y1000

- 1 ea. Encoder Drive Belt P/N Seitz 315MXL

- Remove the existing HSL brake motor from it's mount.

- Remove the Vee Pulleys from the motor and spindle.

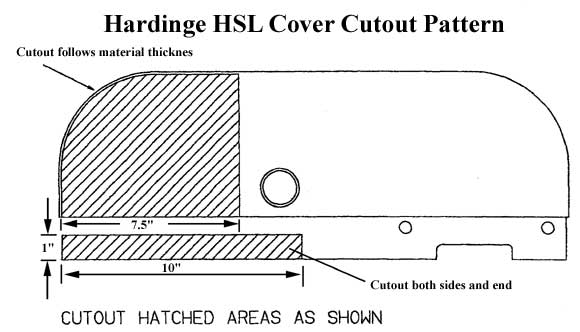

- Remove and cut out the sheet metal belt guard as shown on the HSLCUTOT drawing.

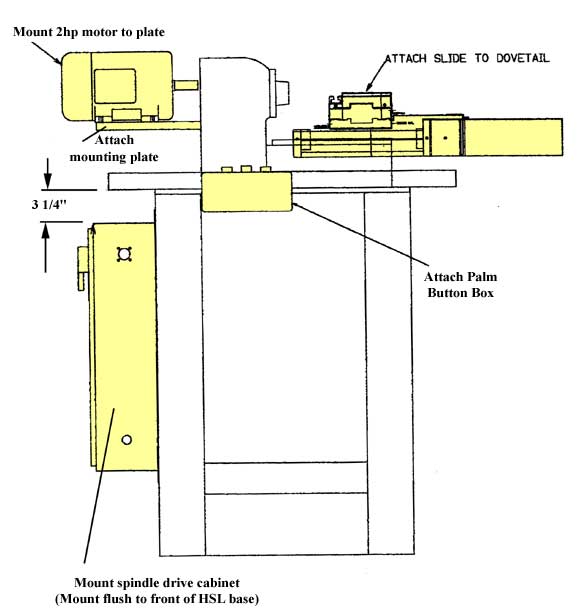

- Install the 3/4 inch aluminum mounting plate.

- Re-install the sheetmetal belt guard.

- Mount the new 2hp motor on the mounting plate, after installing the Goodyear Y-38S-SH pulley and bushing on the motor shaft. Leave the pulley loose for later adjustment.

- Install the Spindle Shaft Pulley Assembly as shown in the FIGURE 1 drawing. This consists of a hub assembly that has the Goodyear Sprocket drive pulley as well as the encoder drive pulley mounted on it. Be sure to install the 1/8 key stock.

- Install the Hardinge locknut on the rear of the spindle, and thread it firmly against the Spindle Shaft Pulley Assembly.

- Install the Encoder Mounting Bracket. This is mounted using the existing 4 hole pattern drilled and tapped in the head casting located beneath the spindle shaft. Mount the Spindle Encoder onto the encoder mounting bracket using the four 10-32 screws and the backing plate. Slip the encoder pulley on the encoder shaft, but leave it loose for adjustment after installing the encoder drive belt. Leave the pulley set screws loose, as the encoder belt will have to be adjusted later.

- Install the Goodyear Y1000 spindle drive belt. Use a straight edge to visually align the pulleys. The pulley on the motor is the only one that can be adjusted. Tension the belt firmly, but not too firmly as this will put undue stress on the Spindle Drive Motor bearings causing premature failure. Tighten the bushing on the motor shaft after verifying alignment

- Install the encoder drive timing belt, P/N Seitz 31 5MXL. Adjust the tension by moving the encoder in the slots in the encoder mounting bracket. The tension should be firm enough to insure the belt won't slip, but not too firm, as this will cause premature failure of the encoder shaft beatings. The alignment of the two encoder pulleys is done by moving the pulley on the encoder shaft. It is properly aligned when the belt tracks without moving off of the pulley that is pressed on the spindle shaft pulley assembly when turning the spindle by hand in both cw and ccw directions while watching the belt track.

This should complete the mechanical portion of the installation.