|

|

|

|

|

|

OmniTurn

Sales Headquarters

40 Allen Blvd.,

Farmingdale, NY 11735, United

States

Tel: (631) 694-9400 | Fax: (631) 694-9415 |

|

|

|

|

|

Automatic Chucks: |

Collets have limitations with workholding

that can be overcome with the right type of chuck. Here

we are offering a few different styles of chucks that

broaden your OmniTurn's usefulness.

Automation of the chuck:

These three chucks all rely on a draw tube actuator.

With the OmniTurn, we use a pneumatic draw tube. The

pneumatics and controls do not change when using the

automatic chuck. M12 and M13 still close and open the

chuck from the program. The operator station buttons

also work the same way. These chucks are easily

integrated with automatic loaders. With the GT-Jr and

with Hardinge attachments, a pneumatic draw tube type

collet closer is required to operate the chuck.

Chuck advantages:

Part variations don't affect a chuck like a collet. A

collet does not like part variations of more than a few

thousandths. If the holding diameter is over or under

size, the collet will not hold the part firmly, if at

all. The chuck jaws move perpendicularly to the

workpiece. The part can vary greatly and the chucking

will still work.

Hold dead lengths in Z even if the holding diameter

varies, unlike a collet that must move in Z to close the

chuck jaws closer parallel to one another. If the

holding diameter of a part varies by .004" in a collet,

the Z location will vary .012". With the chuck, there

will be no change in the part location.

Large jaw stroke makes loading easier: Great for

automation. The jaws open so much that it is possible to

load part with larger diameters and bury them behind the

jaws.

Huge holding force: With the pneumatic collet closer

yielding a pulling force of 1,400# at 80psi, the chucks

can grip with over 5,000#. This is easily regulated with

the pneumatics.

Machinable jaws make difficult work holding applications

easier to set up. By being able to machine the jaws, you

can now hold parts that are not round, require side

loading, or have to be machined eccentric.

The maximum RPM ratings shown are not possible with all

spindle nose configurations and spindle drive types. If

you require higher RPMs, please contact the factory for

application assistance. If you intend to do short cycle

work, also please contact the factory before purchasing. |

|

|

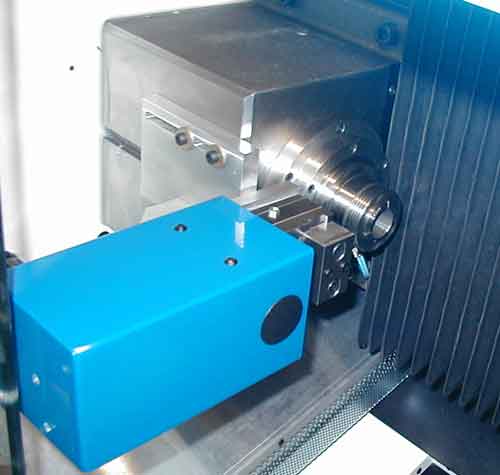

| 3"

diameter, 2 jaw, blind |

4"

diameter, 3 jaw, blind |

|

|

| 4-1/2"

diameter, 3 jaw, 1" thru |

4"

pneumatic, blind |

|

|

|

|

| |